Simulation of shear forces in circular pipelines

In industrial painting technology, paints are usually carried in so-called circular lines from the paint supply room to the paint booths or to the application devices and back to the storage containers.

When pumping around in these lines, the paint used is sometimes exposed to considerable shearing forces, which can lead to long-term damage to the paint. It is therefore important for both paint manufacturers and paint users to know how sensitive the paints used react to this shear stress.

It is therefore advisable to check on a laboratory scale before using new paint systems or when changing recipes whether the paint system is “circualr line stable” and how it behaves in comparison to previously used or alternative recipes.

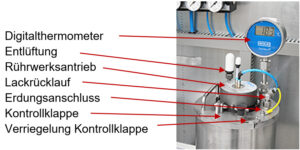

The Paintshearer is ideal for such tests . A paint test quantity of around 5 liters is sufficient for realistic shear stress and, after a relatively short time, provides information about changes in viscosity and/or pressure conditions when pumping the paint around in the test line. Cyclic sampling to check the processing properties and the spray pattern is easily possible. The paintshearer is often designed purely pneumatically for explosion protection reasons, but depending on requirements an electronic control can also be installed. The functional components are integrated in a cabinet. The function of the system can be observed at any time through a glass door.

We can equip the Paintshearer with a wide variety of components, i.e. pumps, paint pressure regulators and hoses from different manufacturers can be used and tested so that the tests are functionally identical to the devices used in many industrial circular lines.

Cleaning the system is made much easier by integrating a pulsed air purge sequence.

Advantages of the Paintshearer :

- Easy to handle

- Provides comparable results in a timely manner

- Simulates concrete circular main situations

- Allows sampling at any time

- Works purely pneumatically

Technical data of the basic device:

- Max capacity : 5 liters

- Operating pressure max.: 18bar

- Compressed air supply 6 bar

- W x H x D mm: 800x2100x600

- Circular line length 10m

- Circular line ID: 6mm

- Double diaphragm pump: 3.5 : 1

- Back pressure regulator 3.5:1

- Agitator motor: 30-300 rpm

- Agitator: VA funnel agitator, electropolished